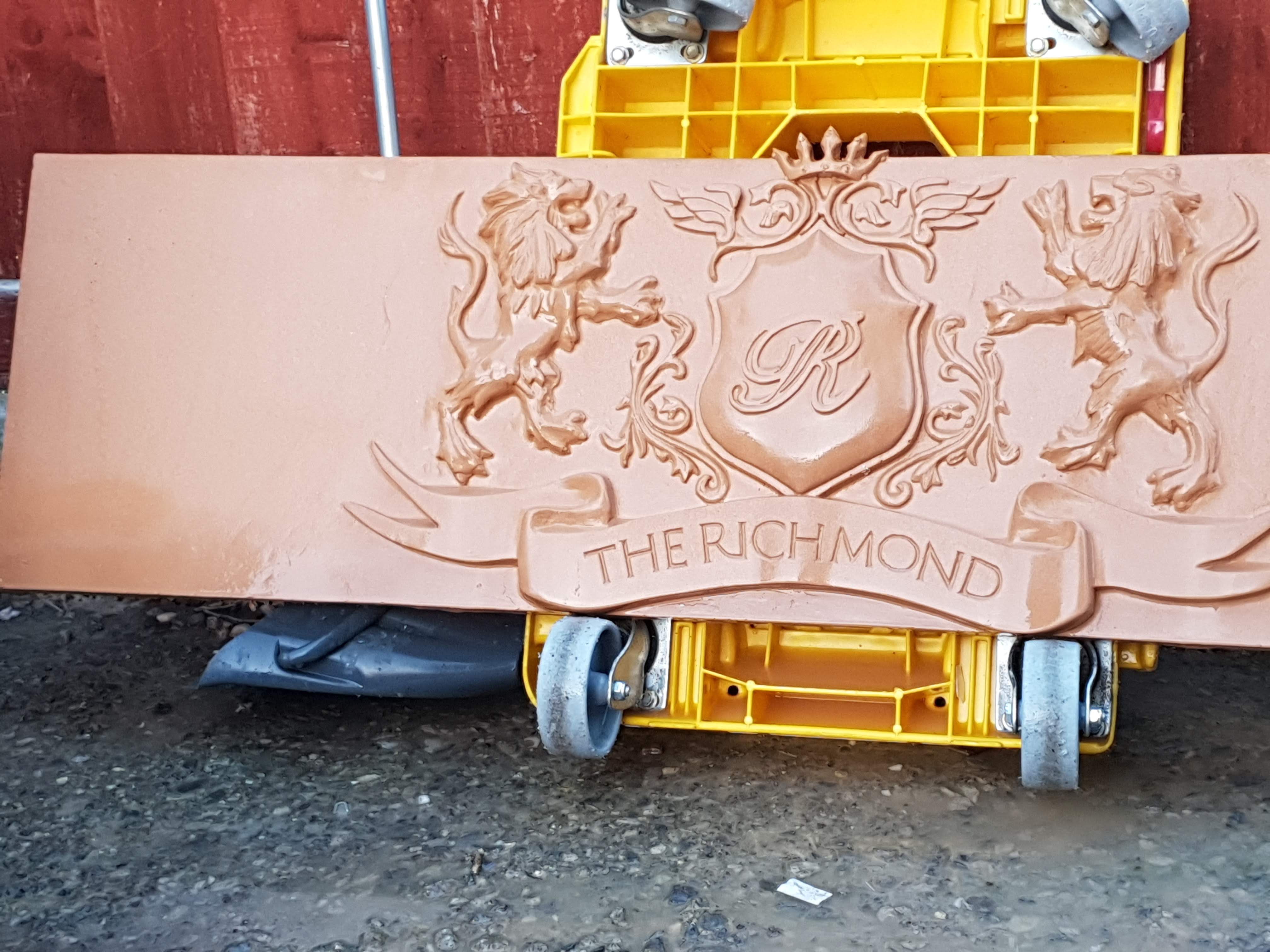

We modelled and produced these cast stone entrance logos for the construction of the Richmond hotel, Liverpool.

The grand entrance to this exclusive 5 star boutique hotel in Liverpool city center was redesigned to incorporate the business logo and we were tasked to design and produce a pair of stone emblems for the client.

We sculpted the model by hand using clay and produced a master for approval. A silicone mould was produced from this and replicated in Jesmonite matched to the colour and constitution of the original stone.